GGF Glass Defects and Guidelines

Queries about glass can lead to a raft of questions.

- Is it a defect?

- How can I assess a mark I’m concerned about in my glass?

- What’s acceptable?

- Does it depend on the size of the glass unit?

- Should there be condensation on the outside of my windows?

This guide is designed to answer Norrsken customers’ most frequently asked glass-related questions.

-

What’s the standard for glass quality?

Information in this article is based on, and compliant with, the standards for Product Quality laid out by the Glass & Glazing Federation (GGF).

The level of imperfection allowed in glass by the GGF is variable and is discussed in more detail in this article.

-

What is the Glass and Glazing federation (GGF)?

The Glass and Glazing Federation (GGF) is the main representative organisation for companies involved in all types of glazing in both commercial and domestic sectors.

The federation is government-recognised and shapes legislation that affects the glass and glazing industry - UK Building regulations being the most widely known example. The GGF is a leading authority on standards for glass and glazing throughout the UK.

Glass types - what’s the difference?

Most glass installed within buildings is manufactured from ‘float’ glass. However, often the glass requires additional processing to allow for safety, security, and energy requirements.

The primary types of strengthened glass are ‘toughened’ (heat treated) and ‘laminated’ glass. Glass can then be coated to provide a specified level of solar control or thermal insulation, screen printed, coated with ceramic frit (fusing ceramic enamel to the glass) or the surface altered, to provide decoration or privacy.

These are discussed in more detail below. Norrsken windows come in double or triple-glazed models. Each pane of glass can be one of three glass types, with additional coatings or visual characteristics.

-

Types of glass pane

Float glass:

made by ‘floating’ glass on a bed of molten metal to create a completely even surface. Float glass is generally accepted to be of the highest visual quality. Glass panels can be manufactured between 2 and 25mm thick, with 4mm as standard.

Toughened glass:

Is thermally treated glass. It is heated to more than 650*C and cooled very quickly multiple times. It is about 5x stronger than float glass and can withstand heavier loads. When broken, toughened glass shatters into many small pieces rather than leaving large shards in the frame. Toughened glass is used for its strength and safe breakage characteristics.

Laminated glass:

Is made from two panes of annealed (float) glass bonded together with a transparent polymer interlayer, typically of polyvinyl butyral (PVB), which keep the glass layers together even when broken and prevent break-up into shards. It is a type of safety glass: openings that may be used as entrances generally take laminated glass to prevent shattering and easy entry, and it is used in upper-level floor-height openings to ensure containment in the event of breaking. Laminated glass comes in thicknesses of 6.4, 6.8, 8.8, 10.8 and 12.8mm as standard.

-

Additional glass options

Low E glass:

our double and triple-glazed units are produced with one or two panes of low-emissivity (Low-E) glass respectively. This heat reflective glass coating is entirely transparent, but reduces heat loss from the building. It allows the warming infra-red rays into your home but reflects back into the room heat that would otherwise be lost to outside.

Solar Control glass:

Has a coating applied to limit the amount of solar gain that the glass produces. This can be provided to reduce overheating on large unshaded areas of predominantly south-facing glazing.

Tinted glass:

Is made by adding small amounts of metal oxide to the glass composition. This reduces glare and modifies the glass colour without changing the basic properties of the glass.

Obscure glass:

Is deliberately produced to distort the view through the glass.

Examples of glass options

-

Atlantic

-

Satin

-

Chinchilla

-

Kura

-

Crepi

Inspiration for your project

From heritage transformations to scandinavian-style passive houses, discover how Norrsken windows and doors transform exceptional homes into extraordinary spaces.

Whether it's converting industrial barns into a contemporary sanctuary or pushing the boundaries of sustainable design in passive houses, our projects span every architectural vision. See how our windows and doors brought your Norrsken neighbours' visions to life.

GALLERY

Which windows are right for you?

Take our short survey to discover the perfect windows for your project.

Standards for faults in float glass

What the GGF deems to be an acceptable fault depends on the size of the glass unit and type of fault.

‘Glass is meant to be looked through, not at’, says the GGF. It is not perfect - and the larger the pane, the less perfect it is allowed to be.

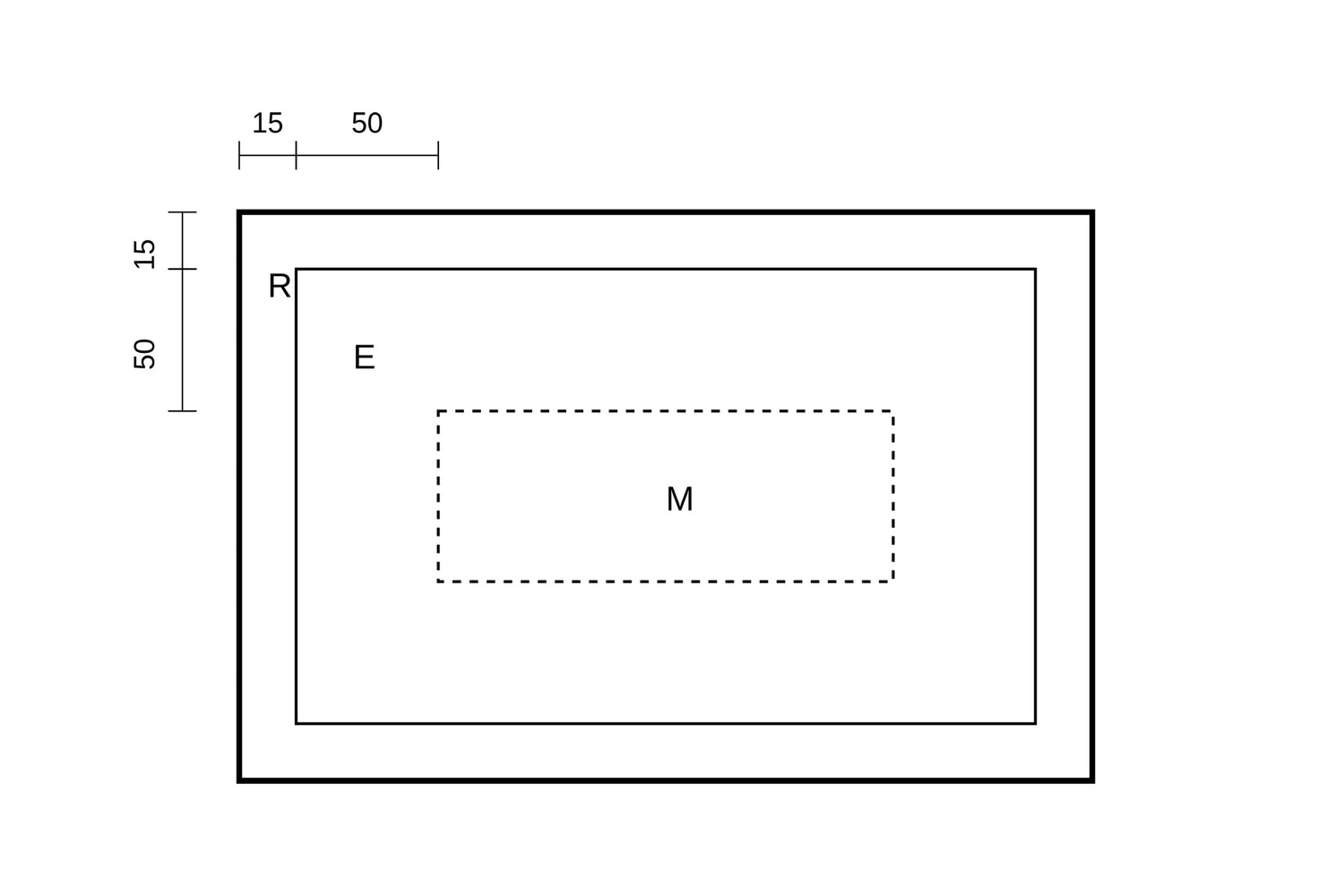

Areas of the glass

The GGF refers to three specific areas of the glass pane:

- Imperfections within 15mm of the edge - ‘Zone R’ according to the GGF, and an area usually covered by the frame or edge seal - are all acceptable regardless of size or frequency.

- Imperfections within 50mm of Zone R - that is, within 65mm of the edge; ‘Zone E’ - are accepted or rejected based on the size of the fault, the size of the glass, and the frequency in which such faults occur.

- Imperfections in the remaining centre of the glass - ‘Zone M’ - are accepted or rejected based on the size of the fault, the size of the glass, and the frequency in which such faults occur.

This is why GGF guidance focusses on the central 80%+ (approximately) of the glass.

Imperfections in float glass are divided into categories and evaluated in the table below

At first glance, this looks like an intimidating amount of information. What is it actually telling us?

- Glass quality is judged by looking through the glass, not at it. This is why the obtrusiveness of faults are judged by how frequently they appear in a given area, and how close they are to the middle of the IGU.

- The closer to the central area of the glass, the fewer faults are accepted. All imperfections within 15mm of the edge are considered acceptable, but the central Zone M is subject to much more stringent requirements for visual quality.

- Determine which area of the glass the fault is in first, then attempt to categorise the type of fault - this may need assistance from our aftercare team, as it will not always be obvious.

- An extra allowance is made in the allowable number of discrepancies for triple-glazed IGUs and / or those containing laminated glass. Pay careful attention to this extra permission when counting any imperfections in these units.

- Follow the guidance at the bottom of this article if you believe the fault falls in a rejection category.

- Use the table to evaluate the fault.

Your questions answered

Have a question? You’re not alone. We’ve answered some of the most common queries about Glass Defects & Guidelines below.

Collapsible content

Does the type of glass I have affect its optical quality?

In a word, yes. The optical quality of transparent glass is directly affected by its manufacturing method.

Float glass generally produces the most even glass surface and the fewest imperfections. Thermal treatment during the toughening process inevitably results in a product of (usually marginally) lower quality than the float glass it is produced from.

Some imperfections, covered in more detail below, are considered normal. Visual quality of laminated glass is influenced by the thickness of the glass panes and interlayers.

What’s normal?

Inherent qualities of toughened glass

Thermal treatment during the production of toughened glass can result in minor imperfections such as bows, roller wave distortion (caused by a reduction in surface flatness, which may cause images reflected in the glass appear to be rippled), a degree of haze, and an effect called anisotropy.

Says the GGF: ‘Anisotropy is the result of stress patterns in the cross section of the glass becoming visible. These areas of stress produce… coloured zones visible in polarised light, sometimes referred to as ‘leopard spots’.

These effects are more noticeable at glancing angles. These are not considered as faults.’

Laminated Glass

Visual quality of laminated glass is influenced by the thickness of the glass panes and interlayers, number of panes, and the lamination process used.

Laminated glass used in Norrsken windows is made by a process called folio lamination, which has a negligible effect on the optical quality of the final glass.

How should you inspect your glass?

Below are seven simple guidelines for inspecting glass.

- Insulated Glass Units (IGUs; the glass in your windows) should always be viewed from the inside at or near right angles to the glass. Inspecting windows from an oblique angle is inherently more likely to display ‘normal’ characteristics of the glass, such as haze, and confuse the observation.

- Inspect from at least 3 metres away - imperfections must be visible from this distance.

- View the glass in natural daylight and not direct sunlight

- There should be no visible moisture on either the inner or outer glass panes

- Strong lamps and / or magnifying glasses should not be used

- A time limit of 1 minute per m² is allocated for viewing

- Focus on the central 80% of the glass (Zone M as discussed below).

What is an acceptable defect? What’s not accepted?

Defects must be visible from the given distance (finding marks at close range and marking them to be visible from further away is not permitted). Obtrusiveness of faults is judged by looking through the glass, not at it.

Standards for acceptable glass are slightly different for float, toughened and laminated glass - so it’s important to check your unit’s glass type(s) as specified in your Norrsken window schedule.

What about marks inside the glass?

IGUs with optical defects (e.g. smears or fingerprints) on the cavity faces - e.g. the inside - of the glass are unacceptable if they are beyond the limits set for stains & residue in the table above.

This also applies to any defects within the 50mm edge zone if they are visibly disturbing.

Standards for faults in Toughened glass

Toughened glass is assessed according to the same criteria as basic float glass - so use the table above to assess the perceived fault.

However, it’s worth remembering that the toughening process can inherently introduce phenomena like bows, roller wave distortion, haze, and anisotropy. So, when evaluating your toughened glass, remember that multiple images, haze, and ‘leopard spots’ are normal and not faults in the glass.

Standards for faults in Laminated glass

Laminated glass panes are evaluated according to float glass criteria, with 25% extra tolerance for the number of faults per laminated pane of glass.

This is because the visual quality of the laminated glass may be worse than that of any component pane - so the greater number of laminated glass panes within an IGU, the greater the likely number of defects and the greater the allowance made for imperfections.

So what should you do if you spot an imperfection?

Here'a a simple checklist if you think there may be a fault in your glass.

- Check the glass type from your Norrsken window schedule.

- Review the guidelines for assessing glass.

- Inspect the glass, noting the size, frequency and type of each imperfection visible from the given distance. Take images if necessary.

- Compare your findings with the GGF table of critical measures for faults, taking into account any tolerance accorded your IGU type.

- If you believe the fault is not acceptable, get in touch with our Customer Service & Aftercare team on 01202 632777 or email support@norrsken.co.uk, who’ll be able to provide more help, discuss the query and your options.

You can read more on the GGF website, or read helpful GGF datasheets on glass quality here.

-

Our Window Range

Premium design, precision engineering -

Our Door Range

High performance insulated entryways

Unmistakably trusted.

The highest compliment is a recommendation. These are the voices of those who placed their trust in us.

"Excellent Company from start to finish… If only every window supplier operated like this! I have used many others over the years on various projects but Norrsken far exceeded all of them… I hope this helps you make a decision for what is probably a large chunk of your budget… They are totally worth it"

Angela Smith

Self Builder

“Having used Norrsken in the past we were happy to recommend them to one of our clients who was looking for the best sound proofing and weatherproofing they could get being set on a hill top overlooking the sea and facing strong westerly winds. They were not disappointed. A quality product, delivered well and on time. Thankyou.”

Ken Pearson

Homeowner

"Fantastic professional service, from the original design to the final installation. The triple-glazed windows and doors that have been fitted to our new house are of a very high quality and look amazing. We definitely made the right choice when we decided to use Norrsken, nothing is too much trouble for them."

Nigel

Homeowner

"I did my research before contacting Norrsken but they had come highly recommended by our Architect for our Passive House self build.

From the first meeting with Nick we felt confident that they were the Company for us."

Ali and Brian Manning

Passive House Self Builders

“The quality of the triple glazed, alu-clad windows and doors is superb. They feel so reassuringly solid ... I opted for a wood stain for the internal finish on the frames, and am so glad I did, as it shows off the beauty of the wood perfectly. The whole process from order to installation went smoothly. I thoroughly recommend Norrsken.”

Gareth

Homeowner

"Norrsken provided attentive service from drawings to on-site installation for our project at National Trust Stourhead and we would definitely recommend and repeat commission them on future projects."

Charlotte Hill-Baldwin

Architect, H-B Designs

“From our very first interaction to the aftercare support, Norrsken has been exceptional. The quality of their windows is outstanding - beautifully designed, expertly crafted, and a real standout feature in our home. They've truly elevated the overall look and feel of the house.”

Neil Southwell

Self Builder Homeowner

“I can highly recommend Norrsken… After much research I found that Norrsken could beat all of the quotes for a high quality triple glazed option. The windows are beautifully crafted and have received lots of positive comments…. I found the whole team at Norrsken incredibly friendly and helpful…”

Douglas Munro

Selfbuilder

Related resources

View all-

The Future Homes Standard 2025 explained

Understand how Future Home Standard (FHS) 2025 will reshape home efficiency, glazing, and construction for modern living.

The Future Homes Standard 2025 explained

Understand how Future Home Standard (FHS) 2025 will reshape home efficiency, glazing, and construction for modern living.

-

Trickle Vents & Building Regulations Part F

Understand how Part F affects ventilation and trickle vent use in your window plans.

Trickle Vents & Building Regulations Part F

Understand how Part F affects ventilation and trickle vent use in your window plans.

-

GGF Glass Defects and Guidelines

A clear guide to the GGF glass standards and what to expect from modern high-performance glazing.

GGF Glass Defects and Guidelines

A clear guide to the GGF glass standards and what to expect from modern high-performance glazing.

-

The EnerPHit Standard

Learn how the EnerPHit Standard makes passive house retrofits achievable, efficient, and future-proof.

The EnerPHit Standard

Learn how the EnerPHit Standard makes passive house retrofits achievable, efficient, and future-proof.